В области глубокой переработки минералов бентонит, благодаря своим уникальным свойствам адсорбции, связывания и тиксотропии, стал незаменимым ключевым материалом во многих отраслях промышленности. Будь то металлургические окатыши, литейные формы, буровые растворы или наполнители для кошачьих туалетов, химическая промышленность, экология — все эти сферы предъявляют строгие требования к гранулометрическому составу и прочности продукции из бентонита.

Однако многие предприятия при модернизации мощностей или строительстве новых производственных линий часто сталкиваются с ключевой дилеммой: покупать разрозненное оборудование по частям или найти надежного партнера, способного предоставить комплексное решение? Последний путь, несомненно, является более оптимальным маршрутом к высокой эффективности, стабильности и долгосрочной прибыли.

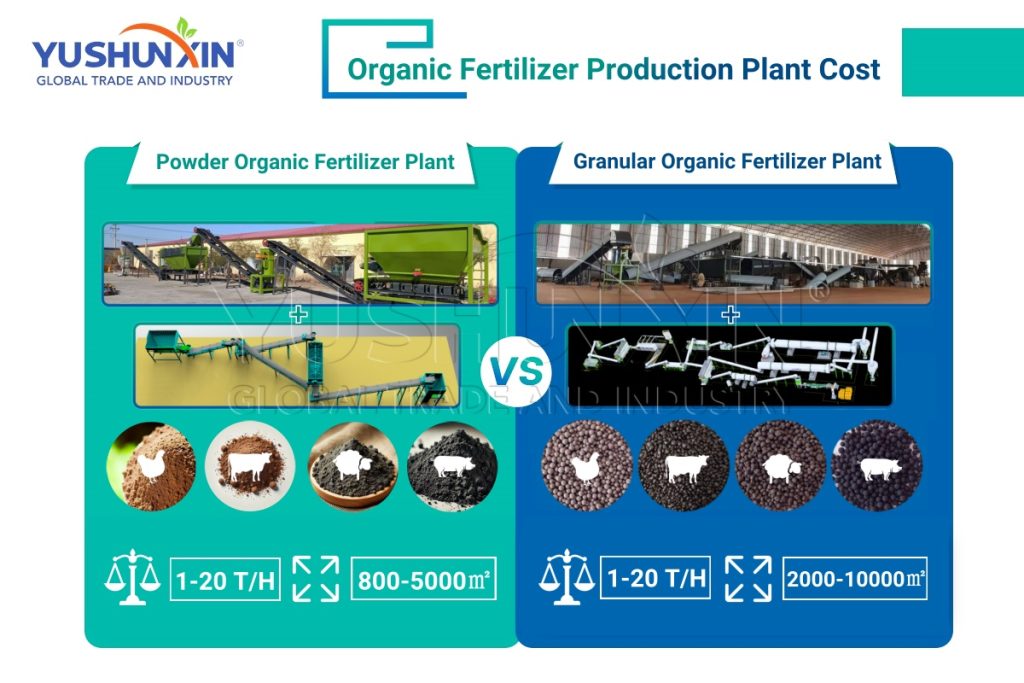

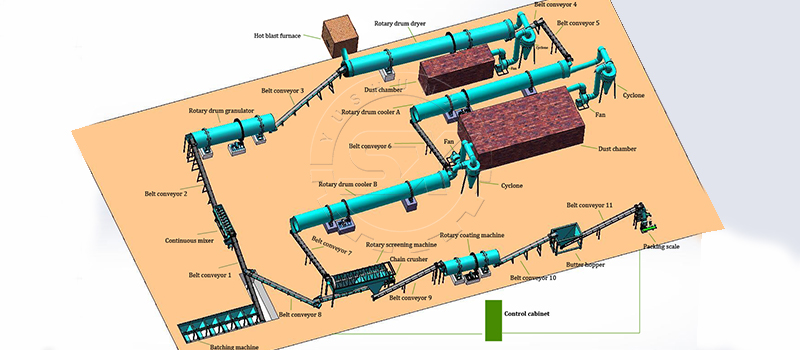

Мы настоятельно заявляем: для гранулирования бентонита мы можем поставить «полный комплект оборудования» под ключ — от обработки сырья до упаковки готовой продукции. Это не просто список устройств, а полная производственная система, прошедшая системное проектирование и инженерную проверку.

Почему стоит выбирать «полный комплект оборудования», а не «покупку отдельных машин»?

Выбрав модель «покупки и сборки отдельных машин», вы можете столкнуться с множеством проблем: плохая совместимость системы, неэффективная технологическая связь, высокое энергопотребление, сложность в эксплуатации и обслуживании, а также размытая ответственность за сервис. Эти разрозненные pain points в конечном итоге формируют «эффект бочки» для производственной эффективности, ограничивая вашу общую производительность и прибыль.

Наша модель полного комплекса решений призвана искоренить эти проблемы в корне. Мы обеспечиваем интегральное проектирование и поставку, гарантируя, что все модули оборудования работают вместе как точные шестеренки, обеспечивая оптимальную производительность системы. Мы фокусируемся на сквозной технологической связанности, гарантируя, что каждый этап — от порошка до гранул — проходит в оптимальном режиме, что значительно повышает выход годной продукции и стабильность процесса. Кроме того, комплексное проектирование с учетом энергоэффективности всей линии позволяет максимально снизить ваши совокупные производственные издержки. Что еще более важно, вы получаете полный спектр услуг от единого ответственного поставщика — от централизованного интеллектуального управления до технической поддержки на протяжении всего жизненного цикла оборудования, делая вашу эксплуатацию более спокойной и надежной.

Ключевые модули линии гранулирования бентонита, которые мы можем вам предложить

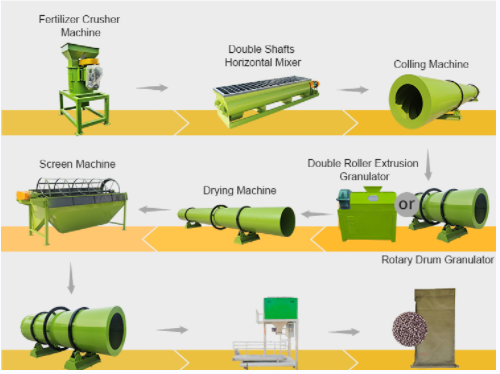

Эффективная и стабильная линия гранулирования бентонита обычно состоит из следующих ключевых модулей, которые мы можем адаптировать под ваши нужды:

1. Система предварительной обработки и транспортировки сырья

Дробление и подача: Обработка возможных слежавшихся материалов, обеспечение равномерной подачи.

Высокоэффективный смеситель (двухвальный лопастной/ленточный): Обеспечивает точное и равномерное увлажнение бентонитового порошка водой (или связующим) — основа для формирования качественных гранул.

Система дозированной подачи: Использование шнековых питателей с частотным регулированием для непрерывной, стабильной и точной подачи материала в основной гранулятор.

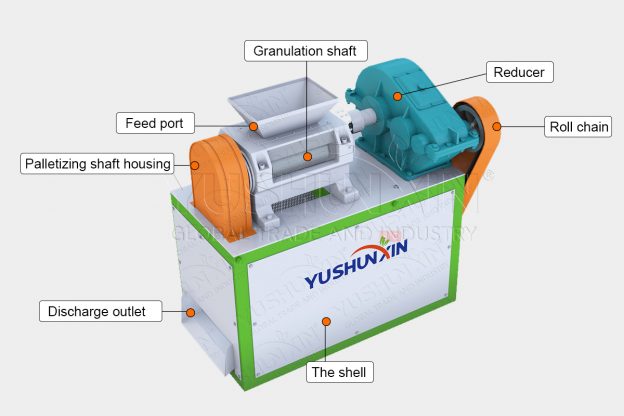

2. Основная система формования

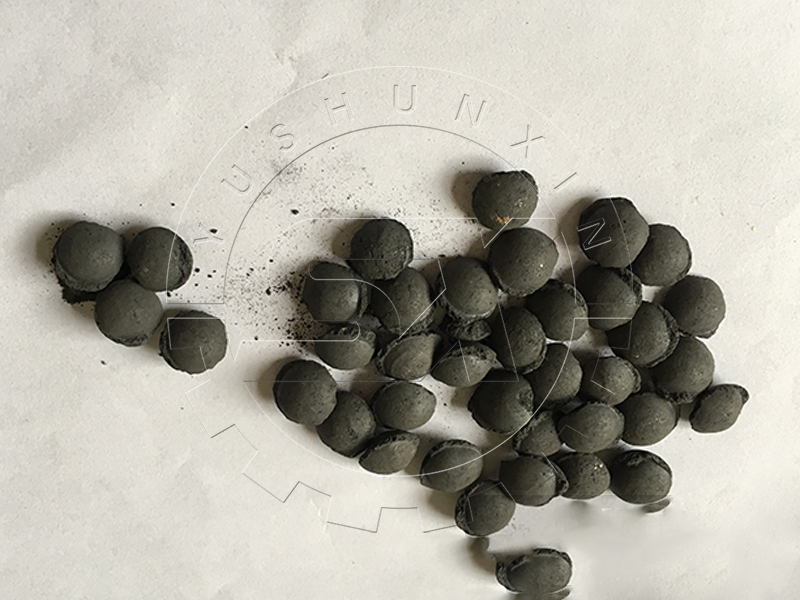

Вальцовый пресс-гранулятор (окатыватель): «Сердце» производственной линии. Мы предлагаем массивную станину, стабильную гидравлическую систему (обеспечивающую постоянное давление формования) и валки из высокохромистого сплава, изготовленные с учетом высокой абразивности бентонита, что гарантирует высокий выход гранул, их большую прочность и длительный срок службы.

(Опционально) Высокоскоростной ротационный гранулятор: Подходит для производства продукции с более высокими требованиями к сферичности гранул.

3. Система обработки и классификации гранул

Дражировочный (окатывающий) барабан: Превращает выдавливаемые ленты или агломераты в однородные гранулы.

Многослойный вращающийся или вибрационный грохот: Точное разделение на фракции: готовый продукт, крупные гранулы (возврат на дробление) и мелкая фракция (возврат в смеситель), формируя замкнутый цикл для значительного повышения выхода годного продукта.

4. Система сушки, охлаждения и упаковки (по требованию)

Вращающаяся барабанная сушилка: Эффективное удаление влаги из гранул для соответствия требованиям к влажности продукции.

Охладитель: Снижение температуры гранул для последующего хранения и упаковки.

Автоматические весы для фасовки: Обеспечивают эффективную и точную фасовку готовой продукции в мешки.

5. Интеллектуальная система управления — «мозг» линии

Интегрированный центр управления на базе PLC, обеспечивающий пуск/остановку, взаимосвязь и блокировки безопасности всего оборудования линии.

Человеко-машинный интерфейс (HMI) для отображения в реальном времени ключевых параметров (влажность, температура, давление, ток и т.д.), поддерживает сохранение и вызов рецептов.

Сеть датчиков контролирует ключевые точки, обеспечивая сигнализацию и автоматическую регулировку некоторых этапов.

Наша добавленная стоимость: ценность партнерства, выходящая за рамки поставки оборудования

Выбрав нас в качестве поставщика полного комплекта оборудования, вы получите:

Профессиональное технологическое проектирование и поддержка испытаний: Мы имеем испытательный центр, где можем провести бесплатные испытания по гранулированию вашего бентонитового сырья и предоставить точные технологические данные и отчет о производительности.

Индивидуальное проектирование и гибкая компоновка: Независимо от условий вашего цеха или специфических требований к продукции, мы можем предложить нестандартные решения.

Настоящая услуга «под ключ»: Мы берем на себя полную ответственность — от чертежей фундаментов и руководства по монтажу до пуско-наладки, обучения персонала и выхода на проектные показатели, чтобы вы могли спокойно начать производство.

Постоянная поддержка в модернизации технологий: Опираясь на отраслевой опыт, мы можем заложить в линию интерфейсы для будущих модернизаций (например, интеграция с MES, добавление систем машинного зрения на основе ИИ и т.д.).

В эпоху перехода обрабатывающей промышленности к интеллектуализации и интеграции, наличие современной, точно подобранной и надежной полной производственной линии для гранулирования бентонита является прочной основой для формирования конкурентных преимуществ предприятия.

Мы предлагаем не просто набор оборудования, а стабильное качество продукции, высокую производственную эффективность и долгосрочные гарантии прибыльности.

От порошкообразного бентонитового сырья до высокодоходных стандартизированных гранул — пусть наше профессиональное комплексное решение проложит вам точный путь к повышению качества и эффективности.

Свяжитесь с нами в любое время, чтобы получить проект технологического решения и рекомендации по конфигурации оборудования, tailored под ваши конкретные задачи. Для получения более подробной информации, пожалуйста, посетите:https://www.granulyator.com/granulirovanie-bentonita/